| Address |

20811 Industry Road Anderson, Shasta Co. CA 96007 |

| Size (MWs) | 50 |

| Dedicated Indirect Jobs | Shasta-Sustainable Resource Management dba SRM is responsible for approximately 75 dedicated indirect jobs, including fuel suppliers involved in collection, processing and transport of biomass fuel. |

| Senate District | SD 1, Brian Dahle, R |

| Assembly District | AD 1, Megan Dahle, R |

| Congressional District | CD 1, Doug LaMalfa, R |

| Website | http://wheelabratortechnologies.com/plants/independent-power/wheelabrator-shasta-energy-co-inc/ |

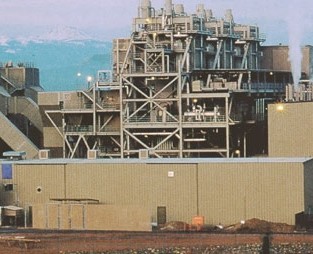

Located in Anderson, California, the Shasta-Sustainable Resource Management facility provides dependable, environmentally safe disposal of wood waste and forest residue from Shasta County and surrounding areas, while generating clean, renewable electricity for sale to the local utility.

Shasta-Sustainable Resource Management is an energy-producing facility with 53 employees. The plant uses wood waste as fuel, thereby converting waste into renewable energy that helps the U.S. decrease its dependence on foreign fossil fuels. Fuel is fed into three independent boilers with traveling grates. These utility-type boilers recover thermal energy in the form of high pressure steam that powers three turbine engines to create electricity that is sold to PG&E. Fly ash captured as part of the combustion process is used as a certified organic soil amendment throughout California’s central valley. Bottom ash removed from the boilers is used as a fill material for projects such as new roads or as alternative daily cover at the local Waste Management landfill.

Shasta-Sustainable Resource Management processes approximately 2500 tons of wood fuel per day and has the generating capacity of 58,000 kilowatts — the equivalent of supplying the electrical needs of 85,000 California homes.

Shasta-Sustainable Resource Management dba SRM |

|

|---|---|

| GENERAL | |

| Area Served | Shasta County |

| Start-up | 1987 |

| BIOMASS COMBUSTION | |

| Heat Rejection | Surface condensers with multi-cell evaporative cooling towers |

| Fuel Handling | Two truck scales, three platform truck dumpers, one hydraulic log loader, infeed/offloader conveyors |

| Furnaces/Boilers | Three Zurn traveling grate, staged combustion furnaces; membrane waterwall boilers |

| Turbine Generator | Three Elliott condensing turbine generators |

| AIR QUALITY CONTROL | |

| Type of Equipment | Three-field, high efficiency electrostatic precipitators |

| ENERGY PRODUCTION | |

| Type of Energy | Electric power and Steam |

| Steam Flow to Turbine | 580,800 pounds per hour @ 850 psig/825°F |

| Electric Power Capacity | 58 megawatts/85,000 homes |

| Cooling System | Re-circulated Evaporative |